Table of Contents

The climate crisis is no longer a distant threat; it is a mathematical reality. To stay within the limits of the Paris Agreement, the world must not only stop emitting carbon dioxide but also begin the Herculean task of removing what is already there. Among the suite of Negative Emissions Technologies, Direct Air Capture (DAC) has long been hailed as the gold standard. It’s a giant mechanical tree that sucks CO2 directly out of the sky.

But DAC has a dirty secret: it is incredibly energy-hungry. Most current systems require blistering heat upwards of 800°C to release the carbon they capture. This energy penalty makes the technology expensive, often costing $600 to $1,000 per ton of CO2 removed.

Humidity-Driven Direct Air Capture (H-DAC). Often called the “Moisture Swing,” this technology flips the script. Instead of using high-grade heat or massive amounts of electricity, it uses the simplest substance on Earth water to trigger the release of carbon. If DAC is the future of our planet, the moisture swing might be the key that finally makes it affordable.

The threat of climate change looms large, and as our carbon emissions continue to rise, the need for innovative solutions to reduce atmospheric CO2 has never been more urgent. Traditional methods of addressing climate change, such as reducing fossil fuel consumption and transitioning to renewable energy, are vital. But even with these efforts, it’s becoming increasingly clear that we may also need to actively remove carbon dioxide (CO2) from the atmosphere to meet global climate targets.

One promising technology in this fight is direct air carbon capture (DAC), specifically humidity-driven DAC, which harnesses the natural moisture in the air to capture and store CO2. In this article, we’ll dive deep into this emerging technology, how it works, its advantages, challenges, and the potential it holds in the battle against climate change.

1. Introduction to Carbon Capture and Climate Change

Before we delve into the specifics of humidity-driven DAC, let’s first understand the broader context. Carbon capture refers to a set of technologies designed to trap CO2 emissions from various sources, preventing them from entering the atmosphere and contributing to global warming. Traditionally, carbon capture is used in industries like cement production, steel manufacturing, and power plants, where large quantities of CO2 are emitted.

However, addressing the rising levels of CO2 already in the atmosphere requires a different approach. Direct air capture (DAC) technologies are designed to capture CO2 directly from the ambient air. Unlike traditional carbon capture, which is often linked to point sources of CO2 emissions, DAC works on a much broader scale and can be deployed almost anywhere, whether near industrial zones or even in rural areas.

While DAC has existed in various forms for years, the humidity-driven version represents a newer, potentially more efficient approach, tapping into ambient moisture to capture and release CO2.

The Energy Problem: Why Heat is a Hurdle

To understand why humidity-driven capture is a breakthrough, we first have to understand the flaw in traditional systems.

Most DAC systems work like a chemical “Velcro.” You blow air over a sorbent (a solid or liquid material), and the CO2 sticks to it. The hard part isn’t getting the carbon to stick; it’s getting it to let go so you can store it underground or use it for fuel. In traditional “Thermal Swing Adsorption” (TSA), you have to bake the material at extreme temperatures to break that chemical bond.

This creates a paradox: to save the planet from warming, we use massive amounts of energy that often comes from you guessed it sources that might produce more carbon. Even with renewable energy, the cost of generating that much heat keeps the price of carbon removal prohibitively high.

2. How Humidity-Driven Direct Air Capture (H-DAC) Work

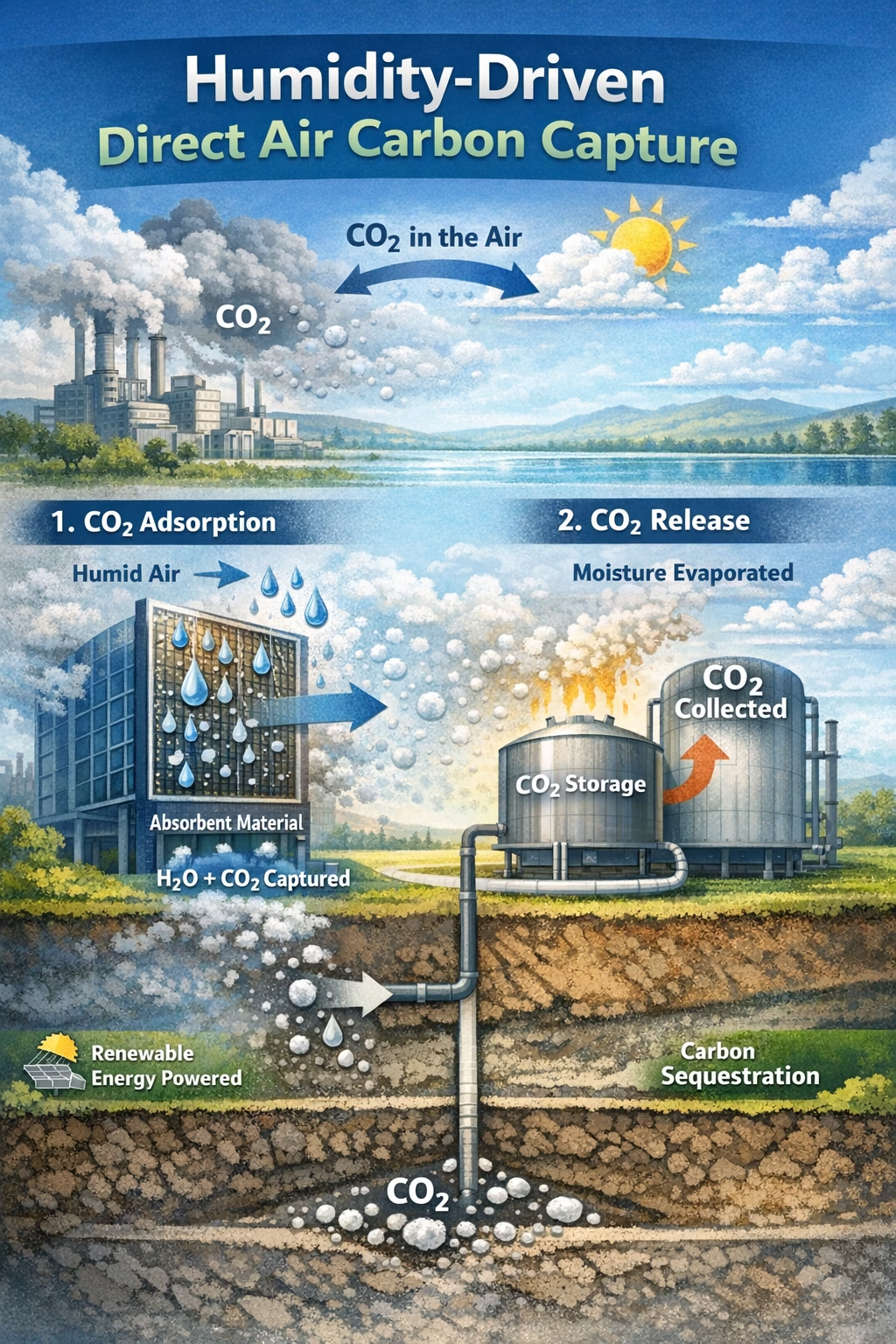

The basic principle of humidity-driven DAC is straightforward. Most DAC technologies use chemicals or materials that can bind with CO2 when exposed to the air. However, instead of relying on energy-intensive processes like heat or pressure to separate the CO2, humidity-driven DAC systems take advantage of the moisture present in the air.

Here’s a simplified version of how it works:

- Step 1 : The Dry State (Capture Of CO2)

- Step 2 : The Wet State (Release of CO2)

Step 1 : The Dry State (Capture Of CO2)

The system uses materials that are hydrophilic (i.e., they attract and hold water). These materials are often designed to be highly porous, maximizing their surface area to interact with the air. When the humidity in the air comes into contact with these materials, the CO2 in the air binds with the water molecules, trapping the carbon dioxide in the process.

When the resin is dry, it has a high affinity for CO2. As ambient air passes over it, the resin acts like a thirsty sponge, pulling CO2 molecules out of the air and binding them to its surface.

Step 2 : The Wet State (Release of CO2)

The moisture and captured CO2 are then collected in a specific environment where the moisture can be evaporated or removed, and the CO2 is released. Some systems use changes in temperature or pressure to facilitate the release, while others might rely on drying the material to force the CO2 to separate.

When you introduce moisture either by soaking the resin in water or exposing it to high humidity/steam the chemical potential changes. The water molecules essentially crowd out the CO2. The resin’s affinity for carbon drops, and it releases the CO2 in a concentrated stream.

3. Technological Advances in Humidity-Driven Direct Air Capture (H-DAC)

Recent advancements in humidity-driven DAC are coming from both universities and private companies. Scientists and engineers are working to improve the materials used for capturing CO2, as well as refining the processes for releasing it.

- Key Innovations in Materials

- Improvement of Processes for CO2 Release

1. Key Innovations in Materials

One of the major breakthroughs has been the development of materials that are specifically designed to absorb and release CO2 in the presence of water vapor. Some of these materials include metal-organic frameworks (MOFs), ammonia-based compounds, and hydrophilic polymers. These materials are often tailored to have a high affinity for CO2 molecules when exposed to humidity.

For instance, MOFs are a class of materials that have a very high surface area and can store large amounts of CO2 in their porous structure. Their ability to selectively adsorb CO2 in the presence of moisture is a key feature that makes them attractive for humidity-driven DAC.

2. Improvement of Processes for CO2 Release

While capturing CO2 is one part of the equation, the process of releasing and storing the carbon is just as important. Humidity-driven DAC systems are focused on finding efficient methods to release CO2 from the materials, using minimal energy. This is a critical area for reducing the costs of DAC systems. Some researchers are exploring temperature swing adsorption, where CO2 is released as the material is heated or dried, while others are experimenting with vacuum desorption methods.

4. Potential Advantages of Humidity-Driven DAC

There are several reasons why humidity-driven DAC has garnered attention from researchers, policymakers, and environmentalists alike:

A. Energy Efficiency

One of the biggest challenges with traditional DAC methods is their energy consumption. Many DAC systems require significant amounts of energy to capture and release CO2, making them expensive to run. By using ambient humidity, humidity-driven systems could lower the energy requirements for capturing CO2, making them more cost-effective in the long term.

B. Scalability

Humidity-driven DAC is scalable in a way that could make it feasible for large-scale operations. Since it uses natural moisture in the air, these systems could be deployed anywhere with high humidity, such as coastal regions, tropical areas, or cities with high air moisture. This gives humidity-driven DAC systems a potential edge over other forms of carbon capture, which are often limited by specific geographic or industrial factors.

C. Sustainability

The idea of using ambient moisture to capture CO2 could make the process more sustainable. Since the system relies on natural humidity, it avoids the need for additional resources like high-temperature heat sources or chemical reactions that require large amounts of energy. This makes humidity-driven DAC a potentially greener solution.

5. Challenges and Limitations

While the potential is clear, there are also significant hurdles to overcome before humidity-driven DAC can be widely adopted. Some of the key challenges include:

- Efficiency in Dry Climates

- Cost of Technology Development

- Carbon Storage and Long-Term Monitoring

1. Efficiency in Dry Climates

Humidity-driven DAC systems rely heavily on the availability of moisture in the air. In dry climates or areas with low humidity, these systems may not work as effectively, reducing their potential application. For regions with fluctuating humidity levels, the efficiency of the system could vary, making it harder to depend on these systems year-round.

2. Cost of Technology Development

Although humidity-driven DAC has the potential to be more energy-efficient, the technology is still in its early stages. Developing the necessary materials and processes, as well as building large-scale facilities, requires significant investment. The high initial costs of implementing this technology could be a barrier to widespread adoption.

3. Carbon Storage and Long-Term Monitoring

Once the CO2 is captured, it needs to be stored in a way that prevents it from being released back into the atmosphere. This could involve storing CO2 underground in geological formations or using it in industrial processes. However, ensuring that the CO2 remains stored safely for the long term is a critical issue that needs to be addressed.

The Geographic Advantage: Where Humidity-Driven Direct Air Capture (H-DAC) Shines

One of the most interesting aspects of H-DAC is its relationship with the environment. Unlike other technologies that work the same everywhere, H-DAC is a “climate-aware” technology.

It thrives in arid (dry) regions. In a desert, the air is naturally dry, which means the resin can capture CO2 extremely quickly. When it’s time to release the carbon, a small amount of water or steam does the trick. This makes H-DAC a perfect fit for regions like the American Southwest, the Middle East, or North Africa—areas that often have an abundance of solar energy but may have struggled to find a role in the green economy.

However, there is a catch: water consumption. In areas where water is scarce, using water to capture carbon can be a tough sell. This has led to the development of “closed-loop” moisture swings, where the water used to release the CO2 is captured, condensed, and recycled back into the system.

The Main Players: Who is Leading the Charge?

This isn’t just a lab experiment; it’s a burgeoning industry.

- Arizona State University (Klaus Lackner): Dr. Klaus Lackner is often cited as the father of DAC. His work at the Center for Negative Carbon Emissions has pioneered the use of moisture-swing resins. His vision involves mechanical trees that stand silently in the wind, capturing carbon through this humidity-driven process.

- 280 Earth: A startup born out of Google’s “X” (The Moonshot Factory), 280 Earth is commercializing H-DAC. They have developed a system that uses waste heat and a moisture-swing cycle to capture carbon more efficiently than traditional methods.

- Skytree and Arbon: These companies are focusing on modularity, creating smaller H-DAC units that can be used for everything from greenhouse enrichment to large-scale atmospheric removal.

Conclusion

We are currently in the Model T stage of carbon removal. The machines are clunky, the costs are high, and the infrastructure is just beginning to form. However, H-DAC represents a massive leap in efficiency. By aligning our carbon capture methods with the natural laws of thermodynamics and the simplicity of the water cycle, we move closer to a sustainable future.

The atmosphere is currently burdened with over 420 parts per million (ppm) of CO2. To bring that number back down, we need to move billions of tons of carbon. In the grand scheme of things, the moisture swing might be the most human-scale solution we have: simple, elegant, and driven by the very elements that sustain life on Earth.

More Details About the Driven Direct Air Capture (H-DAC) Visit This Reaserch Study.

Frequently Asked Questions (FAQ)

1. How is humidity-driven DAC different from traditional carbon capture?

Most traditional direct air capture (DAC) systems are thermal-swing systems, meaning they use extreme heat (up to 800°C–900°C) to release captured CO2. Humidity-driven DAC (H-DAC) uses a moisture-swing. Instead of heat, it uses water or changes in humidity to trigger the release of carbon, which requires significantly less energy.

2. Does this technology use a lot of water?

It does require water to “flush” the CO2 from the sorbent. However, many H-DAC designs are closed-loop, meaning they capture and recycle the water used in the process. Recent studies show that for every mole of CO2 captured, roughly 45 moles of water are used, but research is focused on reducing this water footprint to make it sustainable even in deserts.

3. What happens to the CO2 after it is captured?

Once the CO2 is released from the resin by the moisture swing, it is collected as a concentrated gas. It can then be:

Sequestered: Injected deep underground into rock formations where it turns into stone (mineralization).

Utilized: Used as a raw material for “green” aviation fuel, carbonated drinks, or carbon-cured concrete.

4. Can H-DAC work in humid climates?

H-DAC actually works most efficiently in arid (dry) regions. This is because the resin needs to dry out completely to “recharge” and capture more CO2 from the air. In a very humid or rainy tropical environment, the resin stays wet and cannot effectively pull CO2 from the atmosphere.

5. Is this technology ready for commercial use?

We are currently in the early commercialization phase. While most large-scale plants today still use thermal methods, companies like 280 Earth and Arbon are building pilot plants using moisture-swing technology. Experts believe H-DAC is one of the most likely paths to reaching the “Holy Grail” price of $100 per ton by 2030.